About Our Bond Breaker

A bond breaker is the layer of separator substance applied in different forms between adjoining solid surfaces. It is used to ensure that there is no adhesive molecular bond between the surfaces.

Bond breakers are engineered products that form a membrane, allowing the surfaces to be separated easily. In some instances wax, petroleum-based substances or grease are used as bond breakers, but these chemicals will change characteristics of the surfaces on which they are applied.

Bond breakers are used over concrete surfaces to eliminate or reduce the cracking of slabs due to temperature and moisture fluctuations. Bond breakers also avoid shrinkage cracks on tilt-up walls. Bond breakers are applied on surfaces that will be joined together when the concrete is poured and thus become inseparable. Bond Breakers will eleviate the problem of the surfaces joining to gether and will allow the concrete elements to be seperated.

Bond breakers are also used in breaking the bond between substrate and waterproofing membrane system, thus forming an adjustable bridge, resisting the movement of the water or moisture. Often a time, the importance of bond breaker as an inseparable part of the waterproofing system is being overlooked. If a bond breaker is not applied before the installation of a waterproofing membrane system, there are high chances that the membrane will wear and tear, forming holes, which would allow moisture into the substrate below, rendering the whole purpose of waterproofing system pointless.

They are also used to resists shrinkage cracks, which may appear on the concrete during casting, due to the unexpected evaporation of water from the concrete surface.

Bond breakers are available in different forms, such as liquid and spray.

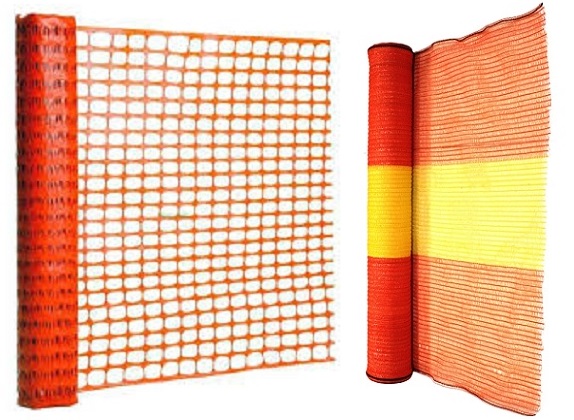

Orange & Yellow Barrier Netting

Orange & Yellow Barrier Netting

Rebar Spacers

Rebar Spacers

Fixing Pliers / Concretors Nippers

Fixing Pliers / Concretors Nippers

Black Annealed Binding Wire

Black Annealed Binding Wire

Flush Cutting Saw

Flush Cutting Saw

Handheld Rebar Cutter

Handheld Rebar Cutter